Digital Twin and IoT

The combination of Digital Twins and IoT offers significant potential to transform various sectors, providing substantial improvements.

Digital Twin is a concept introduced decades ago that refers to the creation of a virtual replica of a physical object, process, or system, allowing simulation, analysis and optimization in a digital environment.

The rapid evolution we have been watching with the Industry 4.0 concept has also contributed to this technology’s growth, especially in manufacturing.

The combination of Digital Twins and the Internet of Things (IoT) is revolutionizing various industries, providing valuable insights, and facilitating informed decision-making.

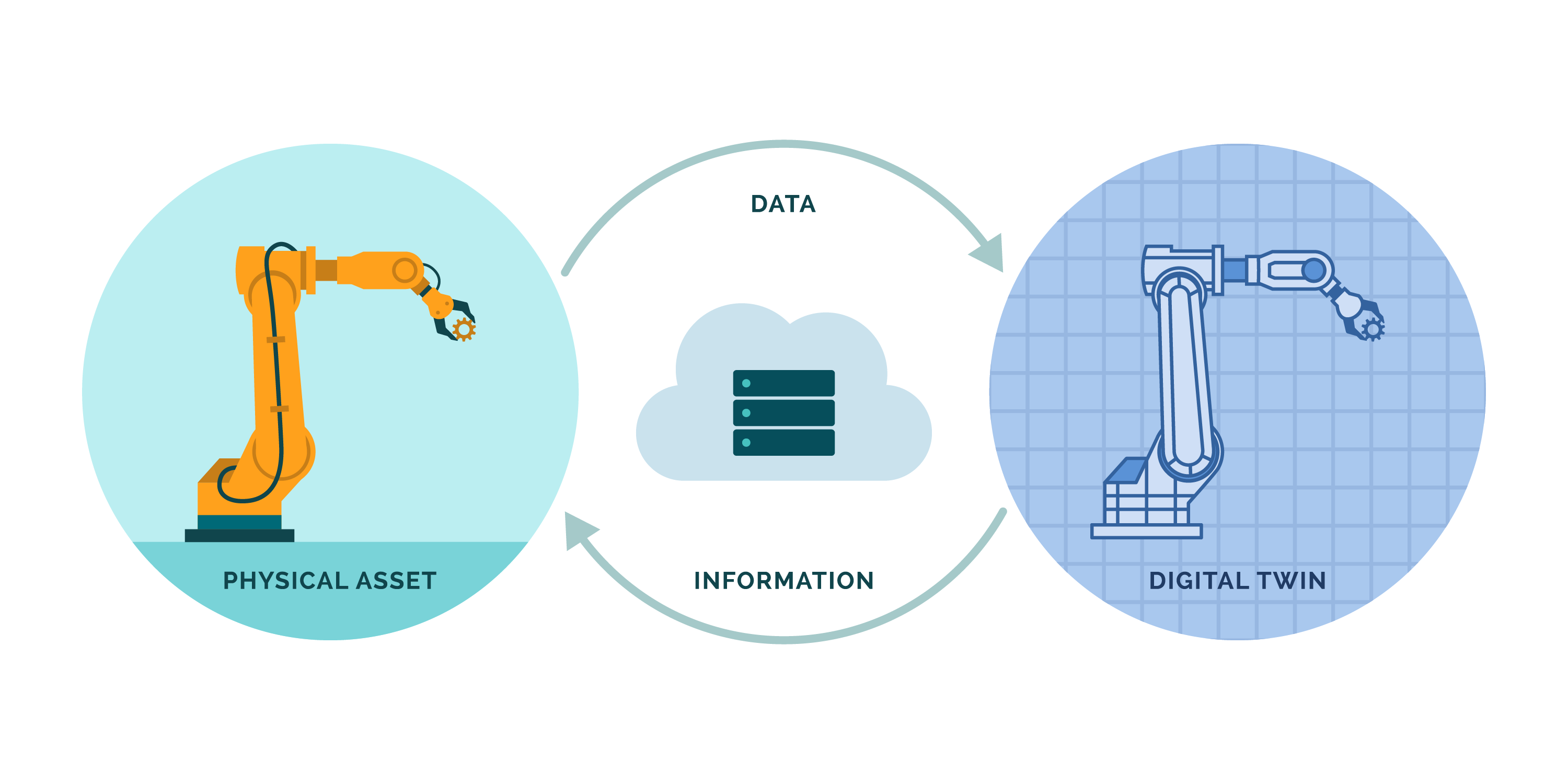

To integrate this technology, first, you need to have IoT sensors installed on physical assets (machines, vehicles, infrastructure) to collect real-time data about their status and performance.

All the collected data should be transmitted to a Digital Twin platform, typically in the cloud. Then, you have the basis to start creating your own Digital Twin. Using the received data, a detailed virtual model of the physical asset is created and continuously updated to reflect real conditions.

With the digital model, you can perform simulations, predictive analyses, and optimizations, providing valuable insights into performance and potential improvements.

Digital Twins or simulations: a matter of scale

Both simulations and Digital Twins use digital models to replicate a system’s processes, but a Digital Twin is a virtual environment, making it richer for study.

The main difference is scale: a simulation typically examines one process, while a Digital Twin can run multiple simulations to study various processes.

Additionally, simulations usually lack real-time data. Digital Twins, however, feature a two-way information flow where sensors provide data to the processor, which then shares insights back with the source object.

With constantly updated data and enhanced computing power, Digital Twins can examine more issues from diverse perspectives than standard simulations, offering greater potential to improve products and processes.

A technology that benefits your assets

All the recommendations and insights generated by the Digital Twin can be applied to the physical asset, closing the feedback loop.

This integration provides a vast list of benefits for your asset:

- Predictive Maintenance: early identification of faults and potential issues, allowing interventions before serious breakdowns occur, and reducing downtime and maintenance costs;

- Performance Optimization: simulation of different operational scenarios to identify best practices, and real-time adjustments of operational parameters to maximize efficiency and performance;

- Product Development: virtual testing of new products and modifications, accelerating the development cycle, and reducing the development costs and time by minimizing the need for physical prototypes;

- Lifecycle Management: continuous monitoring of the lifecycle of assets from manufacturing to disposal;

- Quality and Safety Improvement: rigorous monitoring of operating conditions to ensure compliance with quality and safety standards, and reduction of operational risks through simulations of emergency situations and planned responses.

Tekon has risen to the challenge

Some practical applications of Digital Twins are monitoring and optimizing production lines, monitoring infrastructures and buildings for energy optimization and maintenance, medical equipment for maintenance and optimization, managing supply chains, and managing assets in renewable energy plants to maximize production.

Nonetheless, it is important to consider some challenges in this technology, and the most important one is safety. For instance, it is crucial to ensure that transmitted and stored data is secure against cyberattacks, which means that a Digital Twins system must be carefully implemented.

Another challenge is the interoperability, where it is important in your IoT network to ensure compatibility and effective integration of IoT devices from different manufacturers with different communication protocols.

For these challenges, the Universal IoT Gateway, an advance solution to communicate and share data seamlessly, enables the connection of wireless devices and other ones from third parties by Modbus TCP/IP and RTU, thus guaranteeing data security.

The right combination

Overall, the combination of Digital Twins and IoT offers significant potential to transform various sectors, providing substantial improvements in operational efficiency, predictive maintenance, product development, and lifecycle management.

By addressing the challenges of security and interoperability, with Tekon Universal IoT Gateway, organizations can fully leverage the benefits of this emerging technology, driving innovation and sustainability.

Tekon Electronics continues to reaffirm its contribution to innovation, providing competitive and distinctive IoT solutions.

Join us on this journey towards a smarter and more connected future!

IBM. What is a digital twin. https://www.ibm.com/topics/what-is-a-digital-twin

IT Insight. Digital Twin: o gémeo idêntico da realidade. https://www.itinsight.pt/news/insight/digital-twin-o-gemeo-identico-da-realidade

Forbes. Digital Twin: como funciona a tecnologia que espelha o mundo real. https://forbes.com.br/forbes-tech/2022/09/digital-twin-como-funciona-a-tecnologia-que-espelha-o-mundo-real/